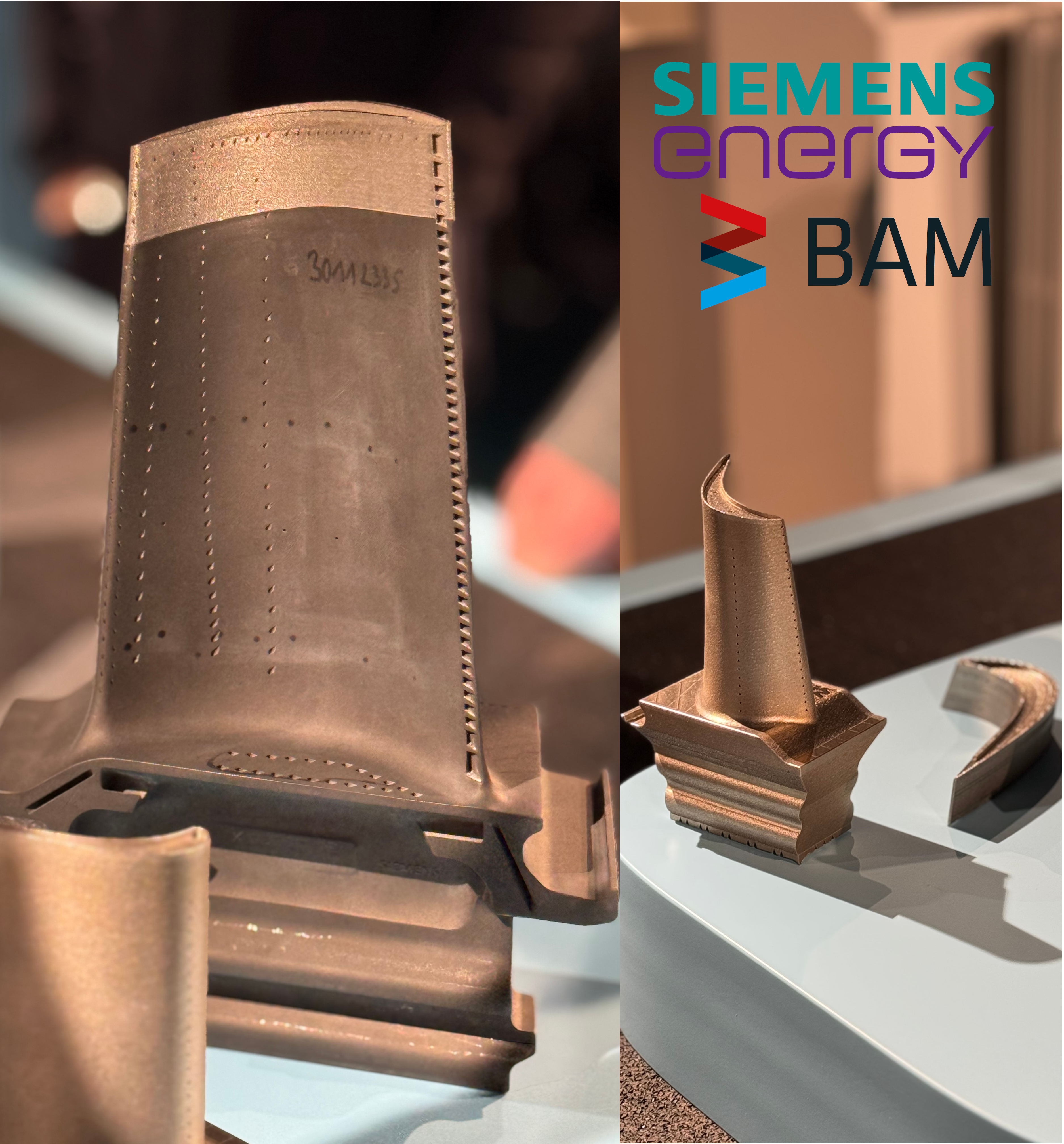

3D PRINTING IN BERLIN

The AMBER ecosystem brings together all the players in additive manufacturing in Berlin-Brandenburg - from research institutions and companies to start-ups, networks and education.

Find out more about industrial applications in Berlin.

Discover how diverse the region is in our interactive map. Filter by categories such as hardware, software, materials, research or networks - and quickly find the right partners for your projects.