![[Translate to English:] [Translate to English:]](/fileadmin/images/projekte/Addgleis_head.png)

Addgleis

Energy-efficient action is becoming increasingly important in all areas of the economy. In the field of mobility, especially in rail transport, lightweight construction is of particular importance in order to reduce energy consumption.

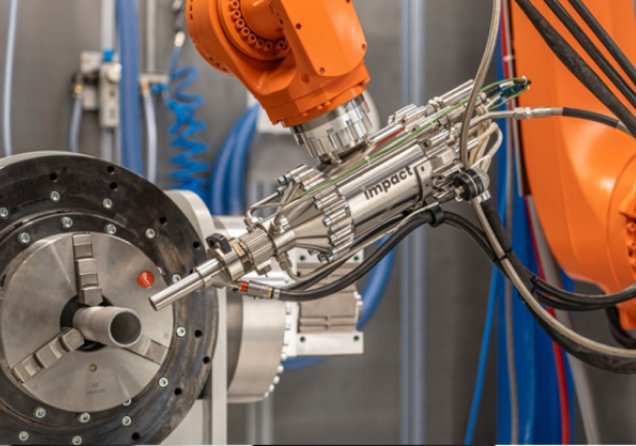

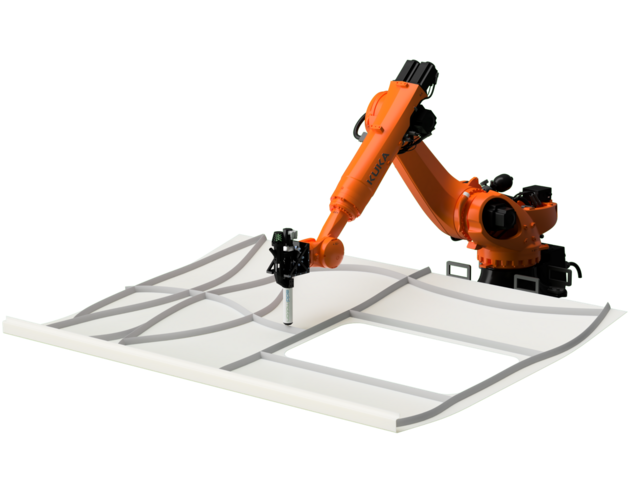

The project partners of the AddGLEIS project are working on the further development of lightweight construction approaches for rail vehicles by applying combined additive manufacturing processes and highly automated robotics. The properties of additive manufacturing processes (e.g., geometric flexibility, shortening of the production chain and improved material utilisation compared to conventional manufacturing processes) are used to realise the goal of lightweight construction.

Additive manufacturing makes it possible to produce weight-optimised components with a topology-optimised design, which are characterized by load-bearing structures that correspond to the actual load curves in rail vehicles. In conjunction with high-performance robotics and a control system regulated by AI algorithms, highly automated additive manufacturing of complex component designs is made possible, free from the restrictions of conventional manufacturing processes.