![[Translate to English:] [Translate to English:]](/fileadmin/images/projekte/MikroG_head.png)

MikroG

The MikroG project (Ultracompact Production Cell for Filament-Based Fabrication of Metallic/Ceramic Components under Microgravity Conditions) serves to develop pioneering additive processes for spacetechnology. Within the AMBER project, it represents the part that develops and foresees technologies for future extraterrestrial human habitats.

The project is carried out in cooperation with XERION Berlin Laboratories GmbH, the Federal Institute for Materials Research and Testing and the Technical University of Berlin.

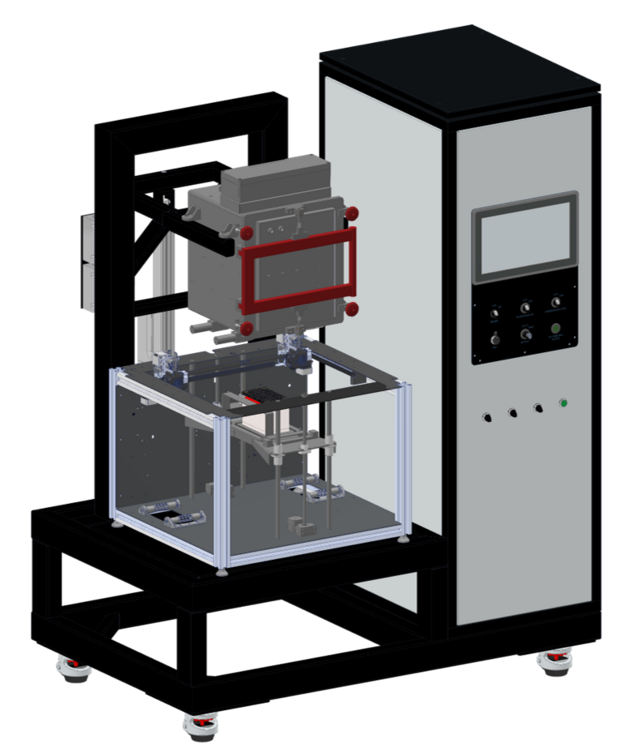

Based on the already available mobile and compact Fusion Factory XS, work is being done on further compacting and merging previously separate units. This will create a complete, smart metal factory in one transportable box. Durable and recyclable spare parts made of metal, for example high-strength stainless steel, can then be produced directly on site. By choosing a process that is independent of gravity, it can also be usedextraterrestrially.

The manufacturing process avoids using any hazardous substances and radiation, such as liquid acids, metal powder spills and laser radiation. This results in an extremely robust metal factory in a transportation box.