ESAF

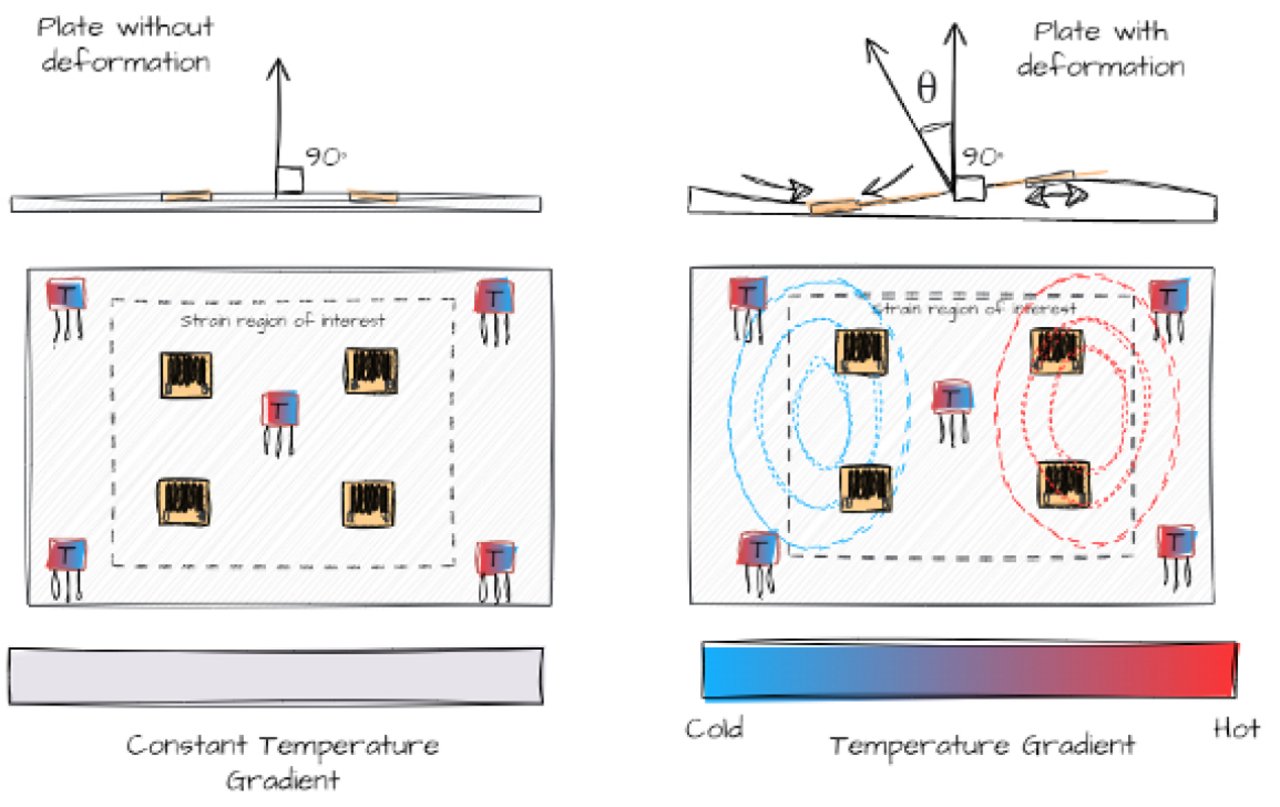

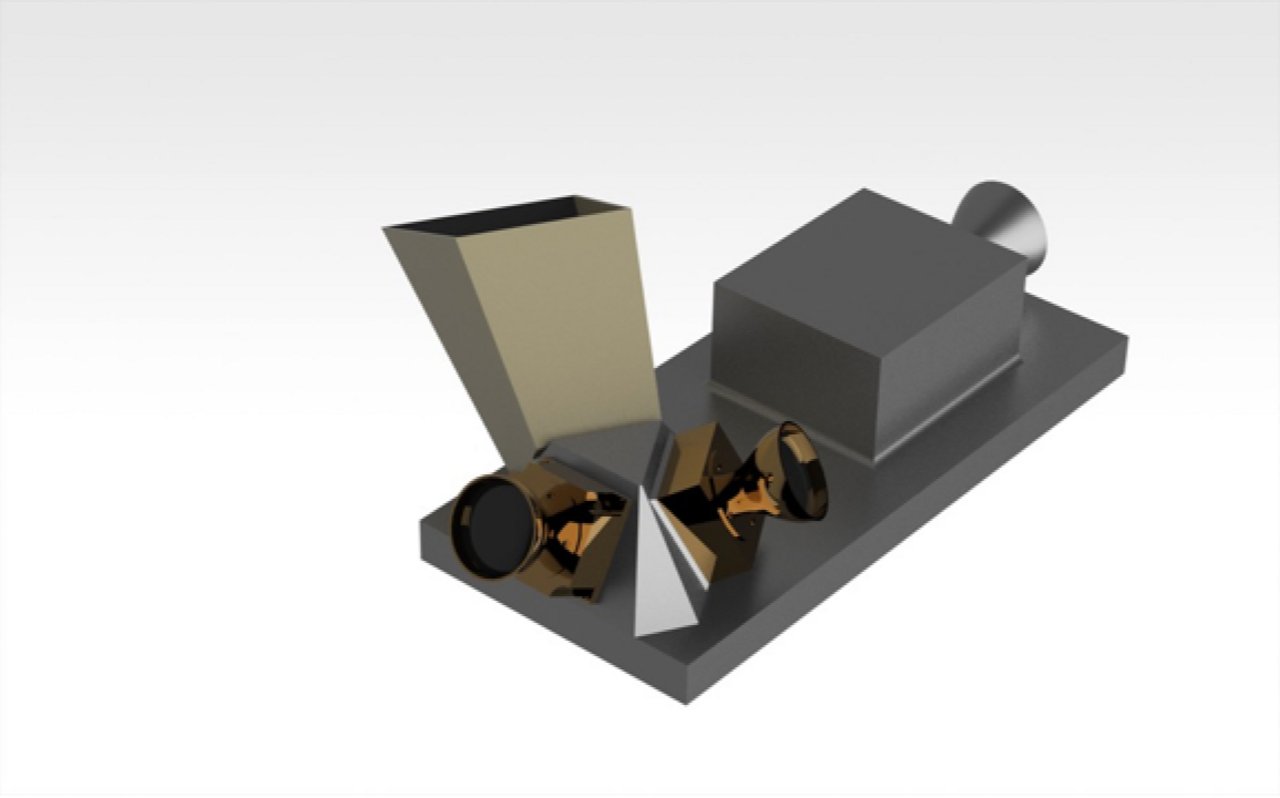

The main goal for the project „Development of an integrative satellite structure by using additive manufacturing processes (ESAF)“ is to design and print a structure on which a star sensor will be mounted on a satellite. A star sensor is a device aboard satellites that determines their orientation in space by analysing the position of stars in the sky. This structure is equipped with temperature and strain sensors to measure the deformations of the structure due to temperature variations and mechanical stresses that a satellite is exposed to in space.

By measuring the deformation caused by thermo-elastic effects of the satellite structure, the alignment error of the star sensor can be determined. This information will provide us with important data to correct and further compensate for the errors caused by the misalignment of the star sensor.