![[Translate to English:] [Translate to English:]](/fileadmin/images/projekte/1000K_Logo_withName_scaled.png)

optiMAL

The aim of the project is to develop a software product based on artificial intelligence (AI) enabling 3D printing of complex components, especially those used in the aerospace industry.

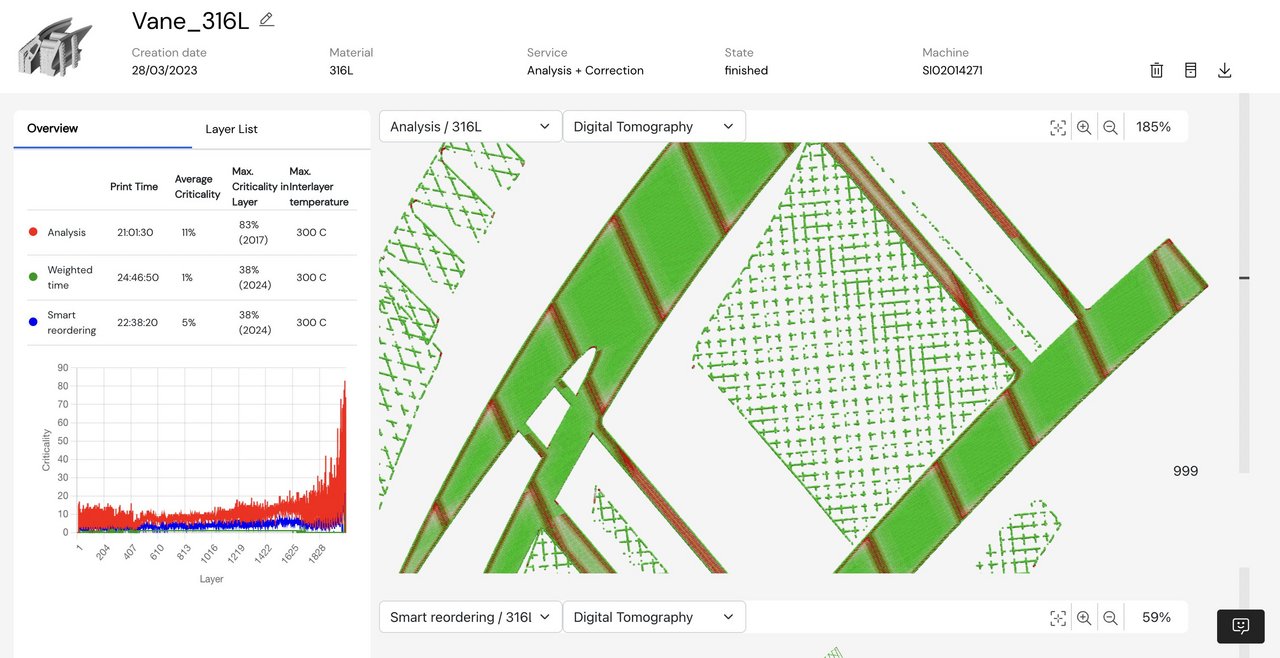

The primary focus is to exploit the AI models to precisely identify and rectify the root causes of deformation and overheating with Laser Powder Bed Fusion (L-PBF). Due to the complexity of aerodynamic and thermal components, defects usually occur during the laser melting process that do not meet the high quality and safety requirements of these industries. The prediction of laser path-related defects is of utmost importance, especially for the aerospace industry, in order to be able to use additive manufacturing on an industrial scale.

By using machine learning and on the basis of physical properties, an optimised laser path is generated already in the component preparation phase, which avoids critical problems, saves time, and reduces reject parts and thus industrial waste. The software is expected to increase the production yield for the aerospace industry to a competitive level of over 90 %. By doing so, we aim to drive the growth of additive manufacturing, ultimately helping it fulfill its market potential.