![[Translate to English:] [Translate to English:]](/fileadmin/images/projekte/perfusionssystem_head.png)

Perfusionsystem

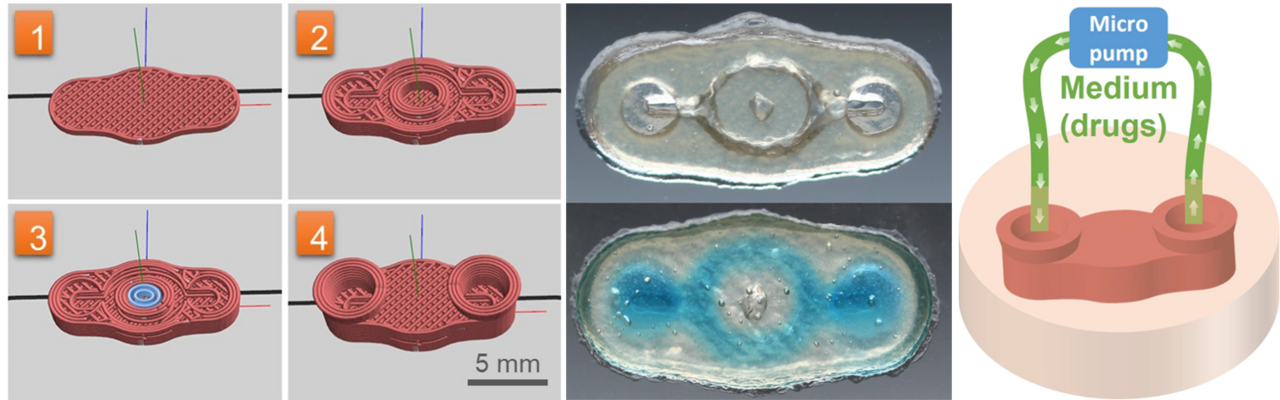

Within the scope of this project, the development of an automated perfusion bioreactor system for the dynamic cultivation of 3D-printed, vascularised organ models is planned. The system will be able to simultaneously operate several independent reactor cartridges, so-called tissue click stations (TCS). The TCSs will each contain two printed organ models arranged in series along a closed media perfusion circuit. Cloud-based control of the temperature and gas mixture in the TCSs will allow long-term cultivation processes, which is crucial for the final maturation of the printed organ models. As a proof of concept, work is being carried out on a lung tumour model. This model consists of human lung fibroblasts embedded with a lung adenocarcinoma supplied by vessels lined with endothelial cells. This project is made possible through the collaboration of the Applied Biochemistry Research Group at TU Berlin, which specialises in 3D bioprinting technologies, and OSPIN GmbH, which deals with automation and scaling of cell and tissue culturing processes.