![[Translate to English:] [Translate to English:]](/fileadmin/images/projekte/ProAStra_head.png)

ProAStra Dental

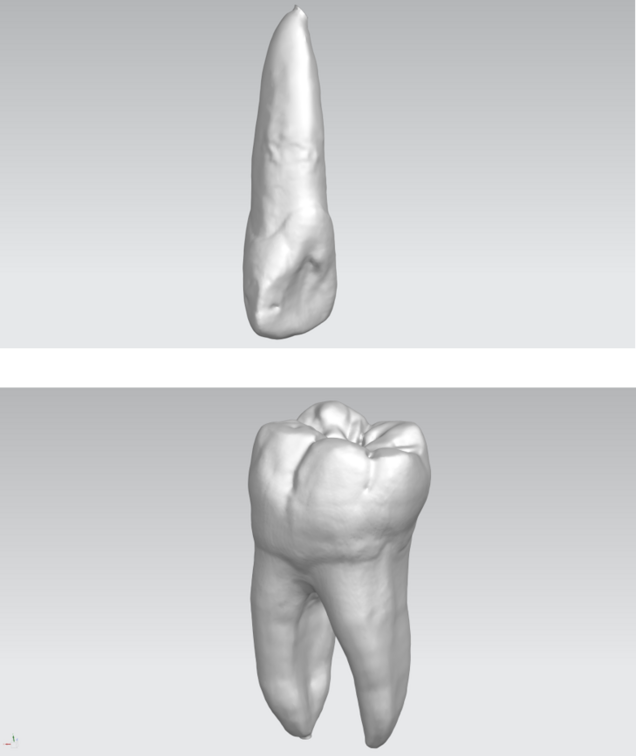

The ProAStra Dental project is pursuing an approach for additively manufacturing new types of dental prosthesis implants with a highly automated, software-supported production chain. The development of a software application with medical design know-how is the core of the project. The software will enable customers to manufacture a customised dental prosthesis implant on additive and subtractive machine tools and support the process chain from the design of the implant to the final machining. A novel implant design optimises conventional implants in terms of ingrowth into the jawbone, force transmission into the jaw and durability. The starting point of the process chain is patient-specific X-ray data in the form of a 3D model of the implant, which is then automatically adapted to the required medical and manufacturing constraints. The geometry resulting from the process then serves as the basis for manufacturing the dental implant by using an automated additive-subtractive manufacturing chain, which is also developed as part of the ProAStra Dental project.